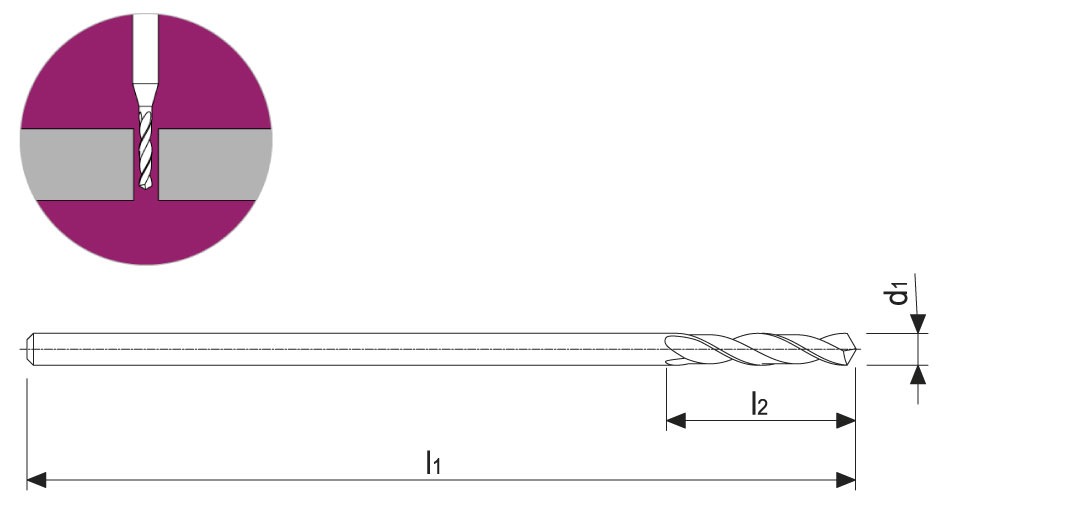

| d1 | d2 | l1 | l2 |

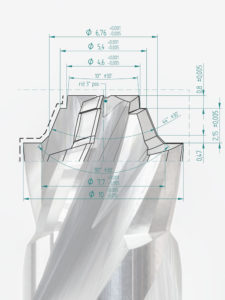

| Coolant holes | Cut | Point angle | Spiral angle | Cutting edges Z |

| 130° | 35° | 2 |

| Coated | Coating type | Material | Material type | Norm |

| No | - | MD | SMG 10 | TUSA |

| Machinable Materials | ||||

| Cod. | Material type | Machinability | Cutting speed Vc | Advancement per revolution fn |

| Recommended Part. recommended Not recommended |

(m/min) |

(mm/rev) |

||

| Unalloyed steels up to 800 N/mm2 | 40 : 60 | |||

| Low alloy steels from 800 N/mm2 to 1100 N/mm2 | 30 : 50 | |||

| Highly alloyed steels from 1100 N/mm2 to 1400 N/mm2 | 15 : 30 | |||

| Ferritic stainless steels | 15 : 30 | |||

| Martensitic stainless steels | 15 : 30 | |||

| Martensitic stainless steels - PH | 15 :30 | |||

| Austenitic stainless steels | 15 : 30 | |||

| Gray/lamellar cast iron | 30 : 50 | |||

| Nodular/nodular cast iron | 30 : 50 | |||

| Drawn aluminum alloys | 60 : 100 | |||

| Die-cast aluminum alloys | 50 : 80 | |||

| Copper | 30 : 60 | |||

| Brass - Bronze | 40 : 70 | |||

| Lead-free brass | 30 : 60 | |||

| Super alloys (Inconel - Hastelloy - Nimonic) | 15 : 30 | |||

| Pure titanium (Grade 2 - Grade 4) | 30 : 50 | |||

| Titanium alloys (Grade 5) | 30 : 50 | |||

| Cobalt Chrome Alloys | 15 : 30 | |||

| Hardened steels up to 55 HRC | - | |||

| Hardened steels from 55 HRC | - | |||

Technical Sheet

Technical Sheet