Regrinding service

With the continued rise in raw material prices, and the long procurement times of raw material, a tool regeneration process becomes increasingly attractive to customers. The incidence of the cost of the material on the price of the tools is considerable and can in some cases even exceed 60%. Why not take advantage of this opportunity?

The Tusa Precision Tools company, thanks to its decades of experience and the professionalism of its team, is able to regenerate its tools in the highest quality even several times, ensuring the initial performance of its products and reducing the costs of use.

We can guarantee personalized services and in case of urgent fast service channels, saving time and money. Contact our technical department and discuss the best solution for your company.

Advantages of regrinding from the original manufacturer:

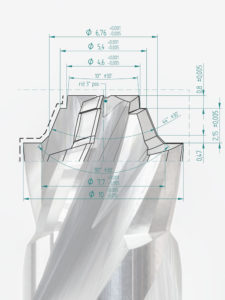

• The tools will be re-sharpened with the original geometries

• Tools will be re-sharpened on machines with original grinding wheels and programs

• If coated, they will be executed with the original coating

So you have a regenerated tool with the same characteristics and performance as a new one.

Upon receipt of the tools, TUSA PRECISION TOOLS SA will carefully check the condition and the wear condition, discarding those that no longer have the conditions to be regenerated. Obviously the discarded and unprocessed tools will not be invoiced.

The tools that will pass this first selection will be regenerated with original geometries and possibly covered with original coating. Before being shipped, all the regenerated tools will be checked again with the usual quality process.