- News

- Company

- Products

-

-

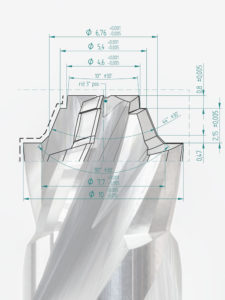

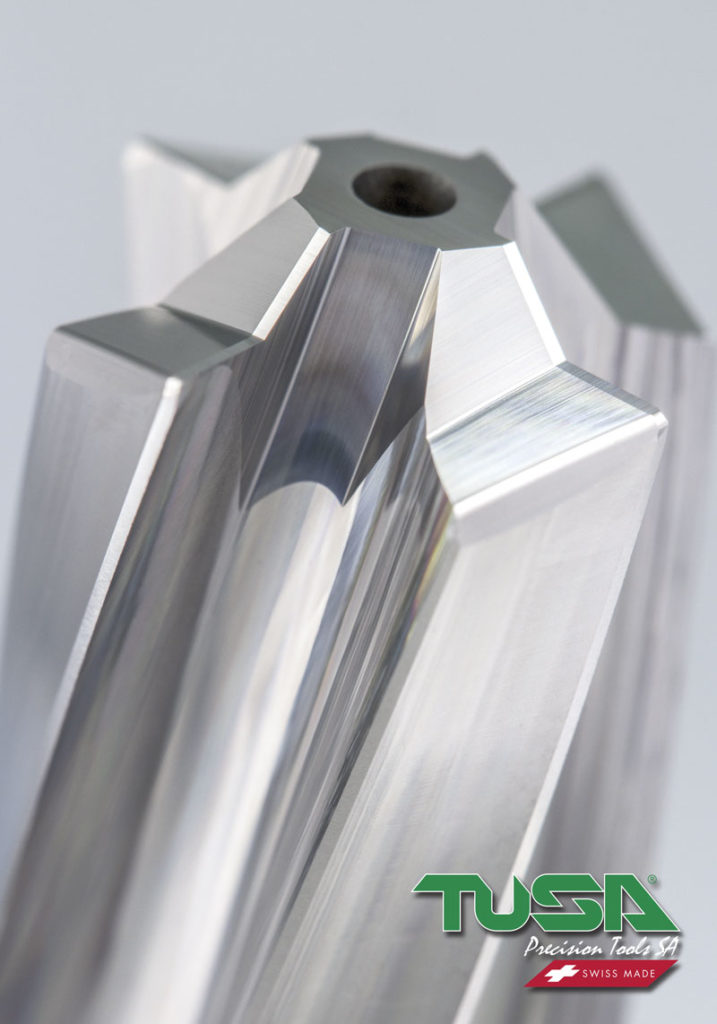

- Drills

- TTD 204, 209, 215 | High performance drills

TTD 206E, 212E, 218E | High-performance drills Excellence

TTD 206E, 212E, 218E | High-performance drills Excellence- TTD203, TTD 207 | Tusa Top Drills

TTD180E | Pilot drill 180°

TTD180E | Pilot drill 180°- MTB27 | Pilot drill

MTB27E | Pilot drill Excellence

MTB27E | Pilot drill Excellence- MTB25 – MTB25_1.100 – MTB30 | Short drills

- MTB 25/3 | 3-fluted twist drill

- MTB33–MTB35–MTB35/L–MTB40–MTB41 | Semi-Decimal-Left-Center Drills

- MTB45 – MTB50 – MTB60 | Long and extra-long drills

- TC35-TA35 | Microdrills

- TA303B | Twist micro-drill with back chamfer

- MTB43 – MTB44 | Micro-center drill

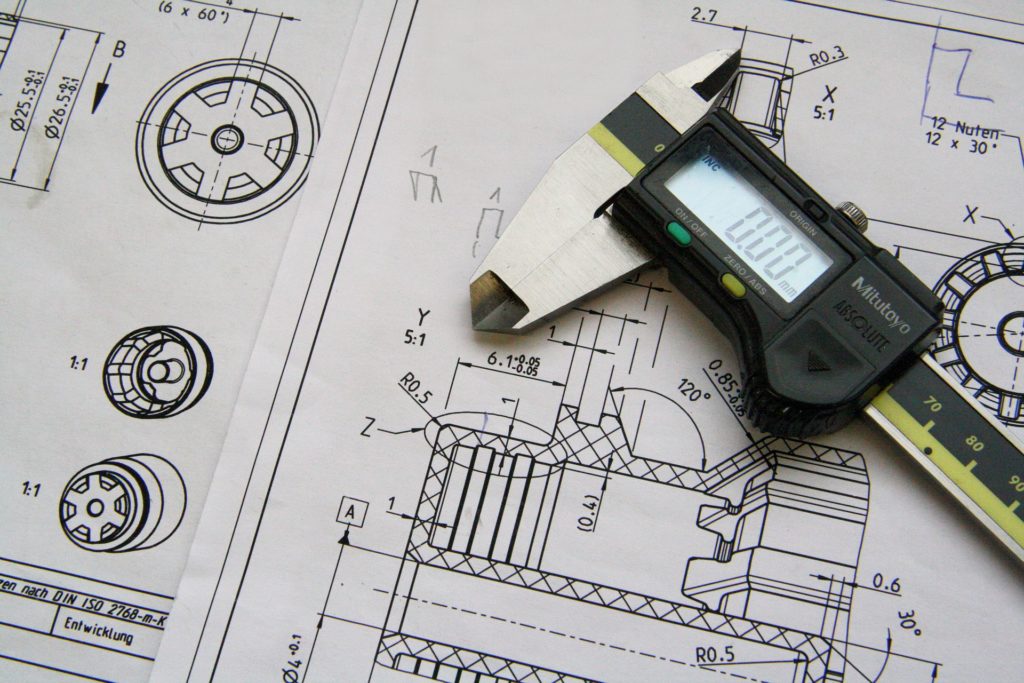

- Reamers

- Cutters

- General sale conditions

- Drills

-

-

- Requests

- Services

- Technique

- Tool Finder

- Contact us

-

-

-

-

Privacy overview

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly necessary cookies

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Cookie Policy

More information about our Cookie Policy