The industrial activity of TUSA PRECISION TOOLS SA consists in the development and production of a wide range of cutting tools in high quality hard metal (tungsten carbide) such as drills, microdrills, endmills, micro-endmills, reamers and circular saws.

The TUSA brand is an established and well-known reality on a global scale and is synonymous with professionalism and high quality level both in terms of product realization and service provided to customers.

TUSA PRECISION TOOLS SA has 60 years of experience in the market of integral tungsten carbide tools.

Typical applications of TUSA products are the tools for high precision mechanical processing, for the aerospace, medical, optical, jewelery and watchmaking, electronic components, automotive sectors.

TUSA PRECISION TOOLS SA, thanks to the purchase of modern equipment and machinery, is able to offer its customers a complete range of solid carbide tools able to best meet the current requirements imposed by the most advanced production techniques.

The technical staff of TUSA PRECISION TOOLS SA is able to guarantee optimal cutting solutions for all machining operations and ensures technical assistance and active consultancy to business partners.

The organizational structure of the company is configured in order to ensure customers maximum flexibility and optimized timing: special solutions can be implemented in a short time even for minimum lots.

Our History

Establishment of the company whose goal is to produce tips for watchmaking

Market launch of new products such as microdrills

The shareholders decide to relocate from Lugano to Mezzovico

Another milestone in our growth: acquiring the first CNC machine

The company achieves its first ISO9001 certification

We evolve into Tusa Precision Tools. Our aim: diversification, growth, and bespoke solutions

Market launch of the first milling cutters for ceramic machining

Expansion of production in a second facility

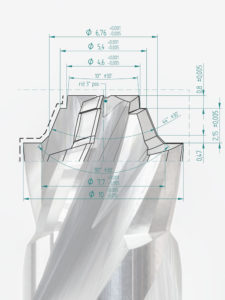

Launch of the new TTDE drill series.